|

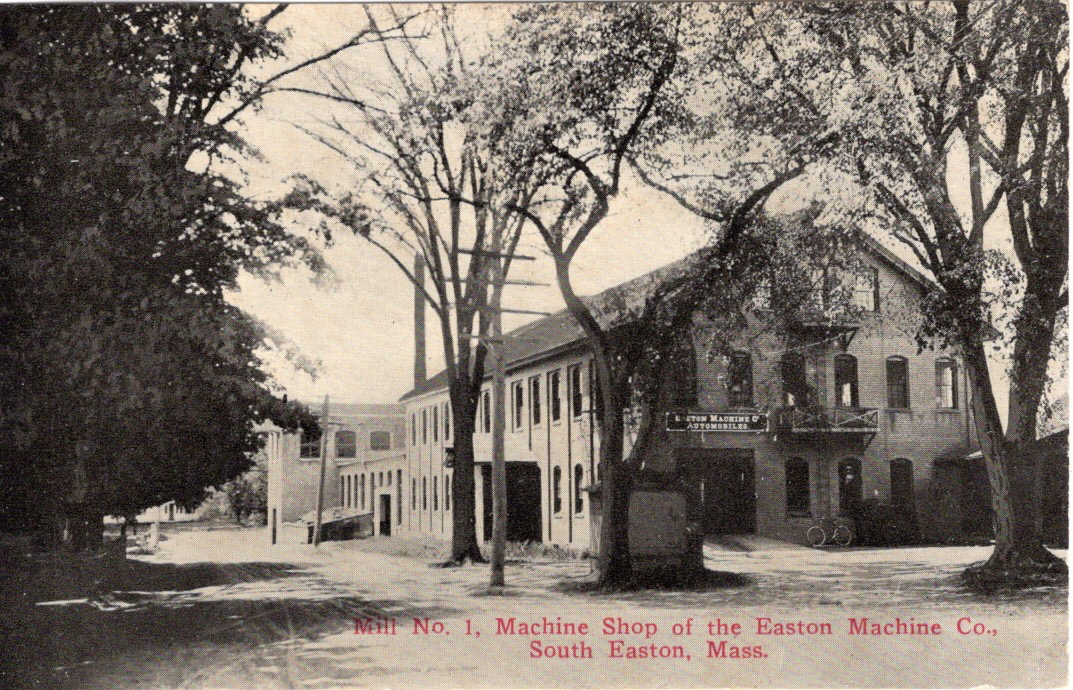

Greetings, and a very happy Fourth of July to all! After a rainy start to the long weekend, it looks like it will be all fireworks, beaches, and barbecues on tap for Sunday and Monday! One of the dominant structures in South Easton is the former Morse mill located at 7 Central Street. Sharing a parking lot with Hennesey’s Package Store, the building serves as a landmark for directions to points south. It seems that many people know the building, but with our 1899 Morse Car now on display, it seems a good time to take a look back at that location and then take a look at the same area today. The Morse Privilege, so-called, really began with the arrival of E.J.W. Morse to South Easton in the 1820’s. He partnered with other people to produce cotton thread at various small mills around the area, probably using each of the smaller buildings to perform separate operations in the manufacturing process. This was not very efficient. By at least 1830 Morse moved a small mill from a nearby location (site of Stonehill College) and began to manufacture cotton thread at the Central Street location, very near the dam and the intersection of what is now Water Street. The business grew, and at one time it was the oldest cotton thread company in the United States. Around 1878, a second, larger mill building was added. This building was constructed of brick (the original mill, originally wood and expanded with other wooden structures over the years, stood at the west end of the new building). With a modern building able to hold modern machines, powered by steam and water, the company continued to thrive. Morse Thread was a trusted brand. The company developed, and patented, Silkateen, a thread which produced a silk-like finished product, as well as other inventions and improvements. After two generations, the company was sold to a major thread firm in England, and by the early 1890’s the building no longer was used to produce thread. A third generation Morse, Alfred Bryant Morse, around 1881 built a steam engine with two friends, William Hadwen Ames and Hobart Ames (on display at the Museum, courtesy of the Morse family) and built a larger, second engine a few years later. With an empty factory and lots of ideas (not to mention a high degree of mechanical aptitude and genius - Morse only completed the eighth grade before working in the business) Morse began a company called the Easton Machine Company. That machine shop began production of highly complex, specialized machinery for making lace, taffy, etc. A terrific fire around 1897 destroyed the old wood mill buildings, and heavily damaged the brick building. Morse rebuilt the brick building, extending it towards the dam, and continued production. Around this time, he took an interest in cars. He began tinkering with a prototype that became our Morse car, and even leased the building to the Cameron Brothers for a while as they began to develop their Eclipse steam powered auto. (This later company was undercapitalized, leading to a number of financial issues, moving around, and eventually failing. Another attempt by the brothers produced the Cameron car, again a short-lived venture.) Morse, with the success from his lace-making machinery and a yearly payment from the former sale of the thread business, was in a strong financial position to try car manufacturing. From 1902 to about 1917, several versions of his Morse Car were produced by the Easton Machine Company. The success of his car business, as well as other machine shop business, created a need for more Manufacturing space, so he built a new mill across the street, which later housed Crofoot Gear for many years. Our old photo is taken from a postcard. The caption “Mill No. 1” at the bottom indicates that the second building existed and dates this photo to around 1912. The brick thread factory is the main attraction here, well-maintained, and features the company sign prominently. Central Street runs alongside the building. A chimney rising from the rear indicates the location of a power plant for the factory. Along the front facade of the building, a large door was cut into the brick, and a cement ramp installed to allow automobiles to enter and leave the building. The second floor housed most of the machinery, and the first floor was used for assembly of the cars. Morse could make parts for other cars as well, so this became a very early repair garage for other people to have their early automobiles serviced. Note the peaceful trees that helped to shade the roads. Today, the building stands as a reminder of what once was. Covered with ivy, 7 Central Street now houses people rather than autos. During the Depression, the Morse family consolidated their business into Mill #2, and the old mill was sold to the Brockton Tool Company, who for decades produced plastic and rubber molds for the shoe industry. The 1980’s move by many American shoe companies to off-shore manufacturing left a hole from which the company could not recover, and before 2000 the building was sold. Today it remains a quiet reminder of two once-thriving businesses. Street lights, traffic signals, and stark pavement now surround the plant in the midst of a very busy intersection with Washington Street. For many years I worked right in front of the old car doors and cement ramp. Opening those doors on hot summer days provided at least a little respite from the heat inside the building. At the left of the new photo are a few trees on a lawn. When I worked at Brockton Tool in the 1970’s and into the late 1980’s, the people who owned the property across the street allowed the workers to have their lunch there every day under those trees, giving us a shady and cool place to eat before the factory buzzer went off and called us back inside for our afternoon shift. Until next week, stay well, and stay cool!

Frank

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Anne Wooster Drury Archives

June 2024

Categories |

Easton Historical Society and Museum

PO Box 3

80 Mechanic Street

North Easton, MA 02356

Tel: 508-238-7774

[email protected]