|

Greetings my friends! Last night brought the first flakes of snow to Easton! A cold and windy night was enough to change a light rain to a slight covering of snow, just enough to remind us that winter is drawing ever nearer with each passing day.

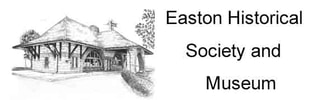

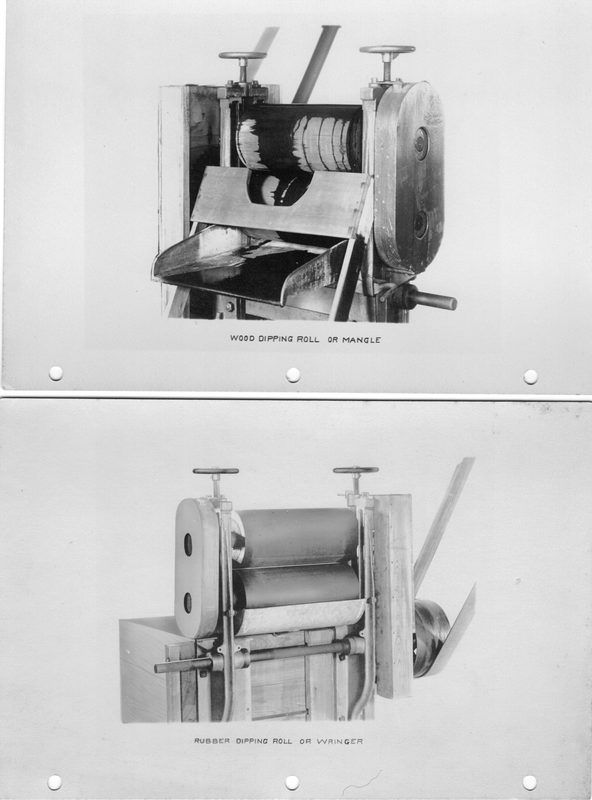

Today we take one last look at machines produced by the Easton Machine Company for the lace industry. One may be very familiar to you, another more obscure, and one that may still be in use somewhere. First up is a rubber wringer. My grandmother had a washing machine in her house that had rubber rolls mounted on the top, where she would "wring" the wet clothing through before hanging them up to dry. This rubber wringer was the industrial version of that same familiar piece of technology that our parents and grand-parents used. After either dyeing or bleaching a material, fabric would be run through this wringer to squeeze out any excess liquid or dye before being placed on a dryer frame. The Morses experimented with the type of rubber used to perfect rolls that could withstand the chemical effects of bleaches and dyes. Another improvement was to enclose the gear mechanisms so they would stay cleaner and run more efficiently. The somewhat obscure second machine featured here is a bit of a mis-nomer: a mangle did just the opposite of what the name implies. It takes any fabric, and through the use of springs and hand wheels, applies hundreds of pounds of pressure to sheets of fabric. Some fabrics, such as linen and damask, need this "flattening" of the fibers to bring out the sheen we are so familiar with. Another application for a mangle is to heat the rolls so that the mangle acts as an iron, removing wrinkles from bolts of material before being wound for sale. Mangles are still in use today by fabric producers, and are a favorite item for those who produce their own specialized fabrics, especially linens and silks. The last machine takes bulk lace and wraps it into the small packages of material we are used to seeing today in fabric shops. This hand winder machine wrapped delicate lace around a piece of heavy cardboard. In the accompanying photo, you can see it in use inside a store. To the left of the winder are a number of lace pieces already wound and ready for sale. I hope you've enjoyed this look at what goes into making lace. The machines that the Morse family developed, improved upon, and supplied through the Easton Machine Company helped to revolutionize the United States lace making industry, making lace more affordable for American consumers. When you put on your favorite holiday outfit this year, take a moment to reflect on what it took to produce that special dress or suit. Stay well, Frank

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Anne Wooster Drury Archives

June 2024

Categories |

Easton Historical Society and Museum

PO Box 3

80 Mechanic Street

North Easton, MA 02356

Tel: 508-238-7774

[email protected]